QUALITY CONTROL

PURELAND

Production QC

Our Quality Inspection Services Mainly Includes:

Sample Checking:

It is an essential step before the manufacturing process, beginning with a physical inspection of a product samplein order to spot anydefects prior to mass production.

First piece/Batch Checking:

Check whether the product style and color are consistent with the specifications and design documents, and check the degree of skill and the quality of materials and finished product based on a design.

In-process Quality Control:

Check the degree of skill and the quality of workmanship throughout the production process.

Inspection Before Packing:

Piece-by-piece inspection, check the degree of skill and the quality of workmanship. For defective products, report and fix the defects.

Packaging Quality Checking:

Check the quality of packaging materials, sealing methods, barcodes, and relevant information...... Make sure every piece of the package meets the specifics.

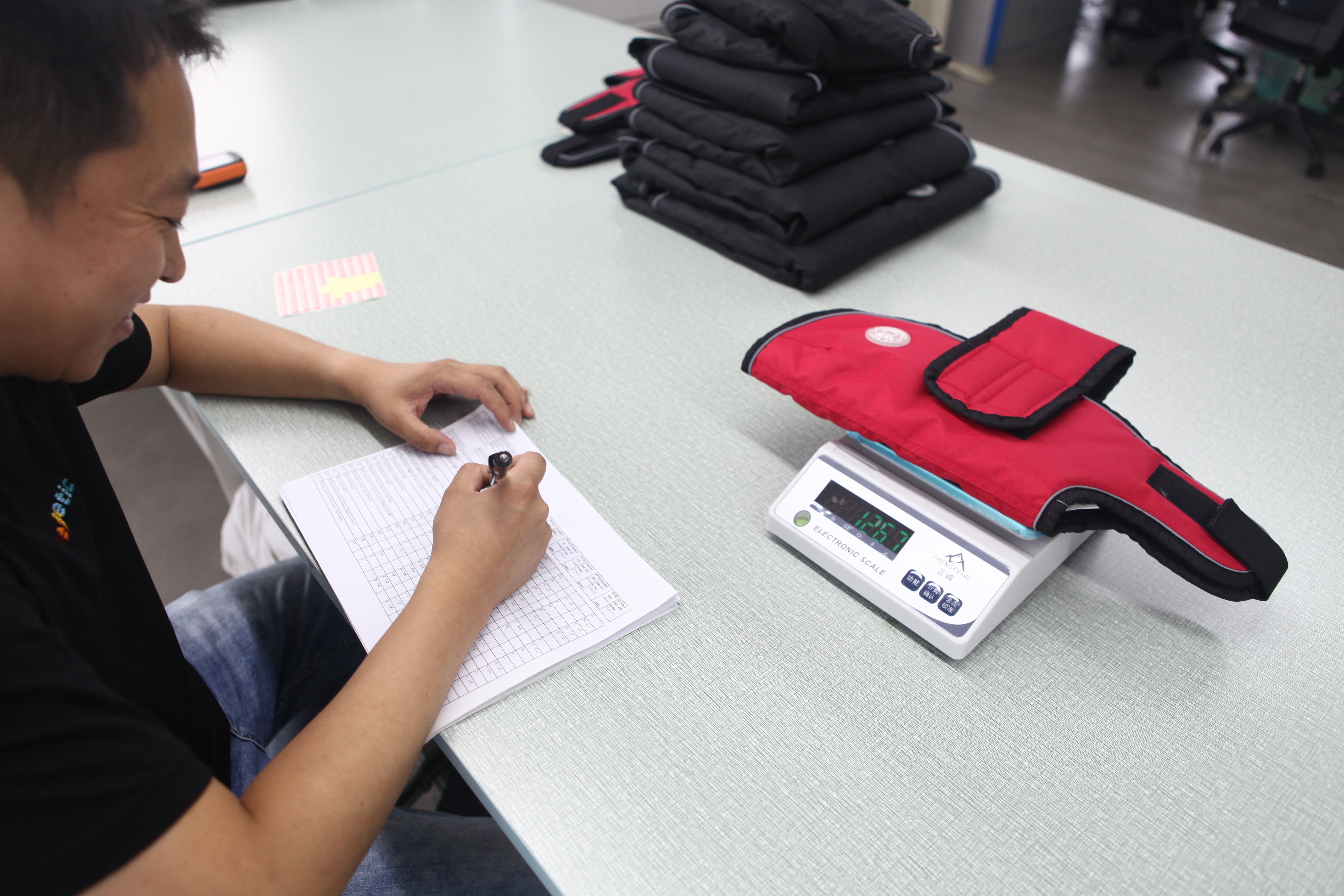

Final Inspection:

In random inspection, the products are checked against a list of criteria defined by the buyer (product quantity, workmanship, function, safety, aspect, size, packing......) this is the only step where the total quantity of products can be counted, and where samples of finished products can be drawn in a truly random manner, and thus be representative of the whole batch.

Shipping Marks & Packing:

Check whether the shipping marks, barcodes and outer box packagescomply with relevant requirements.

Checking for proper outer packaging materials and methods is an essential step of pre-shipment inspection.

Moreover, continuous inspection has the added benefit of making it more likely that risks can be reduced at every step along the way, rather than waiting until the very end of the production.

We continuously assess the quality of ourproducts as well as the pricing of our items as it is important to us that our products exceed your expectations.